We’ve optimized and scaled production for

Delivering Consistent Quality in Every Manufactured Unit

With robust processes and modern manufacturing capabilities, we adapt to your production volumes and timelines, ensuring each unit meets strict quality standards and industry certifications.

-

Consistency via documentation

Consistency via documentationRepeatable Quality Through Documented, Controlled Processes

Documented and controlled processes guarantee consistent results across every production run.

-

Transparency of changes

Transparency of changesTransparent Change Management

All updates are logged, tracked, and implemented quickly through a clear change-flow.

-

Sample validation

Sample validationTesting & Validation Support

We help test and validate proposed solutions to ensure safety, performance, and reliability.

Get more value out of your project with Retail Robotics

-

Reduced Costs

Thanks to our experience and expertise, we optimise every stage of your product development, production and everyday service. We save your costs by implementing innovative ideas for your products and advanced organisational processes.

-

Access to Experts

We provide you with a dedicated team with highly advanced knowledge and experience in product development, manufacturing and service, allowing your company to leverage its expertise without having to invest in extensive training or hiring.

-

Easy to Scale Up

We can quickly scale up our resources and capacity to accommodate changing needs. This flexibility helps you to adapt to market conditions more effectively.

-

Improved Quality and Efficiency

Your company can improve quality and efficiency in the outsourced process. We offer you well-established processes, quality control, and performance metrics, ensuring consistent and reliable results.

Teams and Facilities that Let us Make it Happen

-

Purchasing

-

Mechanical Processing

-

Powder PAINTING

-

Assembly and Electro-Assembly

-

Concrete Casting

-

Quality Control

-

Packing & Logistics

-

Purchasing

Strong partnerships mean reliable supply and execution

Our Purchasing and Cooperation Department ensures that every machine starts with carefully selected materials and components. By cultivating trusted relationships with suppliers, they secure the best balance of quality, cost, and delivery time.

-

Transparent Cooperation

-

Long-term Supplier Partnerships

-

A Keen Eye for Market Opportunities

-

-

Mechanical Processing

Precision that Shapes Performance

Our Mechanical Processing department transforms raw materials into durable, high-accuracy parts that define the quality of the finished machines. Every cut, drill, and mill operation is performed with precision to ensure flawless assembly later on.

-

Modern CNC Equipment

-

Skilled Operators

-

Strict Adherance to Tolerances

-

-

Powder Painting

Protection and Aesthetics Combined

This department applies specialized powder coatings that not only protect surfaces against wear, corrosion, and weather but also add an attractive finish to every project. Visual impact meets industrial durability.

-

Attention to detail

-

High efficiency and quality assurance procedures

-

-

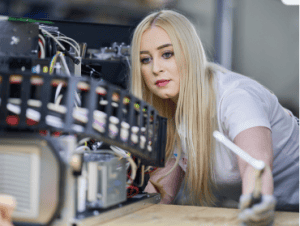

Assembly and Electro-Assembly

Where Ideas and Designs Become Machines

In this department, mechanical parts and electronic systems come together. The team oversees complete assembly, wiring, and system integration to bring each project to life.

-

Based on Cross-disciplinary Expertise

-

Compliance with Modern Standards

-

-

Concrete Casting

Strength at The Very Core

Thanks to our warehouse expertise, the entire machine – including concrete bases – can be produced within a single facility, which reduces production and logistics costs while shortening lead times.

-

Precise Casting Methods

-

Dedicated Mold Design

-

Continuous Material and Process Quality Monitoring

-

-

Quality Control

Every Detail Checked, Every Standard Met

This department ensures that only machines meeting rigorous requirements leave the factory. Each unit undergoes functional, visual, and safety inspections at multiple stages of production.

-

Integrated Quality Management

-

Product Audits Compliant with VDA 6.5

-

-

Packing & Logistics

Safe Delivery Right on Time

The journey from factory to client is managed with care. Machines are carefully packed to withstand transport conditions and ensure they arrive ready for immediate installation.

-

Expertise in Self-service Machine Packing

-

Trusted Logistics Partnerships

-

We’ve a Refined Way to Get Success

Taking you from vision to production in 5 straightforward steps. See the timeline below to learn how it works.

-

1. Quick Quote

You will receive the initial cost estimate in just a few days after reaching out to us.

-

2. Document review

We analyze your documentation (including a DFM review), suggest possible changes, and prepare the cost breakdown.

-

3. Initial Sample

At this stage, we confirm that all technical requirements are met, which ensures smoother production and higher customer satisfaction

-

4. Mass Production

Scalable, quality-driven manufacturing with full communication and flexibility

-

5. Optimization projects

Constantly improving materials and production processes to speed up manufacture and reduce costs

More about Serial Production of Machines and Devices

Didn’t get the answer for your question? Find them.

-

What types of machines and components do you produce?

We specialize in self-service machines such as RVMs, parcel lockers, vending kiosks, and custom components designed for serial production.

-

Do I need to provide complete technical documentation?

Yes, we normally build on your technical documentation, but our engineers can step in with advice and adjustments to make it production-ready.

-

What is the minimum production batch you accept?

We focus on serial production and larger volumes. Typical projects involve hundreds to thousands of machines, not one-off prototypes.

-

How do you ensure consistent quality?

Our production follows documented and controlled processes, ISO-certified standards, and strict EU regulations to guarantee repeatable quality.

-

Can you adapt to design changes during production?

Yes. We use a transparent change management process with full traceability, ensuring updates are implemented quickly without disrupting production.

-

Do you support testing and validation of solutions?

We assist in testing and validating proposed solutions, helping to identify potential issues early and ensure market readiness.

-

How long does it take to launch my product into mass production?

Depends on documentation, component availability, and machine complexity. Thanks to our experience, we manage the ramp-up phase efficiently, which speeds up the transition to full-scale production.

-

How do you handle logistics and delivery?

We manage end-to-end logistics, ensuring on-time delivery to European markets with proven shipping and packaging solutions.