We’ve optimized and scaled production for

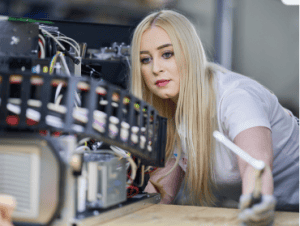

Transforming Proven Ideas into Market-Ready Products

Our team bridges the gap between initial prototypes, pilot production, and full-scale manufacturing—helping you streamline development steps, align designs with production requirements, and accelerate time to market.

-

serialization

serializationDesign for Manufacturing

We adapt prototypes to meet industrial standards and make sure they’re ready for efficient and repeatable manufacturing.

-

documentation

documentationDirect Access to Engineers

Our experts structure and validate documentation so that every process step is clear, compliant, and production-ready.

-

know-how

know-howRapid Launch Capability for Early Market Traction

Clients gain direct access to our manufacturing and logistics expertise, further reducing their operational risks and accelerating market entry.

Get more value out of your project with Retail Robotics

-

Reduced Costs

Thanks to our experience and expertise, we optimise every stage of your product development, production and everyday service. We save your costs by implementing innovative ideas for your products and advanced organisational processes.

-

Access to Experts

We provide you with a dedicated team with highly advanced knowledge and experience in product development, manufacturing and service, allowing your company to leverage its expertise without having to invest in extensive training or hiring.

-

Easy to Scale Up

We can quickly scale up our resources and capacity to accommodate changing needs. This flexibility helps you to adapt to market conditions more effectively.

-

Improved Quality and Efficiency

Your company can improve quality and efficiency in the outsourced process. We offer you well-established processes, quality control, and performance metrics, ensuring consistent and reliable results.

Technical and Implementation Department

Knowledge Transfer

You will work side by side with specialists experienced in diverse self-service machine projects.

By sharing their know-how, they strengthen your project and help secure long-term success.

Cross-disciplinary Expertise

Our technical team brings together mechanical, electronic, and production specialists, bridging disciplines to deliver integrated, high-quality solutions.

From Prototype to Scale

At every stage of your project launch, our technical department is here to support you – turning your concept into a scalable, repeatable, and quality-assured solution.

Clear and Transparent Communication

Our specialists remain in contact with you every step of the way – they listen, analyze, adapt, and overcome your challenges, making sure you never stay in the dark.

We’ve a Refined Way to Get Success

Taking you from vision to production in 5 straightforward steps. See the timeline below to learn how it works.

-

1. Quick Quote

You will receive the initial cost estimate in just a few days after reaching out to us.

-

2. Document review

We analyze your documentation (including a DFM review), suggest possible changes, and prepare the cost breakdown.

-

3. Initial Sample

At this stage, we confirm that all technical requirements are met, which ensures smoother production and higher customer satisfaction

-

4. Mass Production

Scalable, quality-driven manufacturing with full communication and flexibility

-

5. Optimization projects

Constantly improving materials and production processes to speed up manufacture and reduce costs

More about Production Launch and Technical Support

Didn’t get the answer for your question? Find them.

-

Do you help optimize designs for manufacturing?

Yes. Our engineers apply design-for-manufacturing improvements to reduce costs, speed up assembly, and ensure quality at scale.

-

What support do you provide after launch?

We stay engaged – offering continuous technical support, quality monitoring, and process improvements for smooth scaling.

-

How fast can you launch my product into mass production?

Timelines depend on factors such as the quality of technical documentation, component availability, and the machine’s complexity. But because we successfully launch a dozen new machines into serial production every year, our process is fine-tuned and proven. This experience allows us to handle challenges efficiently – and often achieve results that feel close to impossible.

-

Which industries do you serve?

We focus on self-service machines and components: RVM, parcel lockers, vending kiosks, and more – always tailored to client needs.

-

Are your processes aligned with European standards?

Yes. Our production meets strict EU regulations and are certified to ISO 9001 standards, ensuring safety, durability, and consistency.

-

How do you protect client IP?

We only manufacture based on your documentation. You remain the sole owner of your IP – safeguarded by strict confidentiality.

-

Why choose you over other suppliers?

We offer: 1) Proven track record of working with global leaders. 2) Complete support – from design optimization to logistics. 3) Fast, scalable, and flexible production. 4) Deep expertise in self-service technology.

-

Do you assist with certification issues during the transition from MVP to production?

Yes, we ensure that our solutions comply with standards and support the certification process in cooperation with the relevant institutions.